What is the current situation?

Nowadays, as work is becoming more and more flexible, the desire not to be tied to a fixed workplace is also getting stronger. This is partly possible due to the communication of digital devices of all kinds with each other. In a European survey, 70% percent of executives in the DACH Region said, that the pandemic is likely to accelerate their digital transformation. This is why more and more pathology research institutes are also looking for ways to work digitally and automatically in laboratories.

What are the difficulties in digitizing a laboratory?

We all understand that digitization makes sense. But the digitization process of entire workflows is by no means trivial. Think about when you last installed a technical device, whether at home or work.

Did it work smoothly right from the start?

Was the operation immediately clear or did you first have to get used to the changeover?

Often none of this is the case.

If you now look at the same process in research laboratories, where the equipment is technically highly complex on the one hand and the workflows are strictly regulated on the other, this change is even more complicated and requires a thorough understanding of different technologies, IT structures and given process flows.

Stay Ahead with Insights from Precipoint!

Welcome to our newsletter! Be the first to know about our latest products, services, webinars, and happenings in PreciPoint. Don't miss out on this opportunity to stay informed. Subscribe to our newsletter today!

By clicking “Subscribe”, you agree to our privacy policy.

What is the difference between stand-alone devices and digital workflows?

Transition from Stand-Alone Tools to Connected Systems

Up until now, devices are bought for the laboratory as stand-alone tools. A microtome, for example, is obtained to cut samples, a light microscope is used to examine specimens, and so on. They don’t necessarily need to fit together. This is different from digital workflows. When we talk about smart factories and smart labs, devices are no longer disconnected from each other, but they constantly send and process information to each other and work in unison.

Seamless Information Flow with Digital Slide Scanners

Take, for example, a slide scanner. Once the information on the physical glass slide is digitized, it can easily be sent to a wide range of connected systems. The scanner sends the information to an image management platform from where it can be retrieved by the Viewer software, shared for collaboration with third-party systems, or archived and documented. But even before the slide arrives at the scanner, it can be tracked and accounted for, so you know exactly where it is in every step. But this also means all components have to be connected. This is why we first need to look closely at the processes.

How to find a strategy for creating digital workflows?

Understanding the Complexity of Process Flows

To create a successful digital change, the basic structures of different laboratory processes must first be understood. For this purpose, it is recommended to analyze the individual process flows and then map them. This often turns out to be very complicated. Processes can be very intertwined and often run in parallel.

Assessing the Level of Digitization

Once the mapping is done, it is necessary to get an idea of the extent to which the laboratory has already been digitized. This assessment helps in identifying the existing digital infrastructure and understanding the areas that require improvement or transformation.

Digitization of Laboratory Workflows

Enhancing Workflows with Digital Technologies

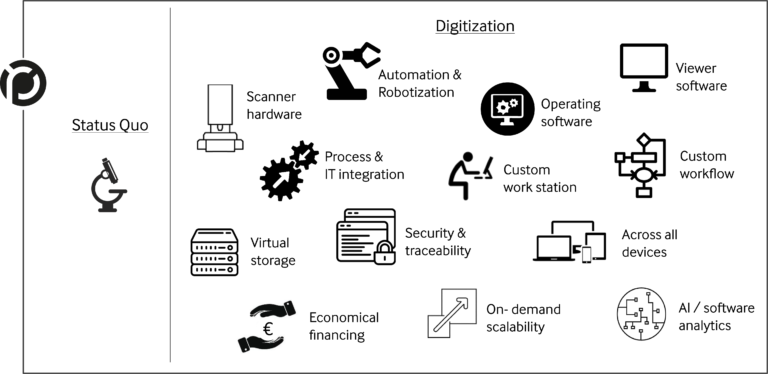

This analysis serves as the starting point to digitize each workflow. To think of new devices only makes sense after all current workflows are understood, and plans are made on how they can be replaced or enhanced with digital ones. Some examples of technologies that could be used to achieve a higher level of lab digitization include:

- Slide scanners

- Staining devices

- Various A.I. software

- Viewer software

- Image management software

- IT integration

- Barcode scanners and printers

- Data storage (local or cloud)

Effective Integration of Digital Technologies

There are many different providers for the mentioned technologies. Therefore, the important part is to know how to put them together into effective workflows that match the needs of each laboratory. Care must be taken to ensure conformity with applicable regulations in the laboratories, which should be checked and continuously guaranteed during the digital transformation process.

Are AI and automation going to compete with us?

Addressing Concerns of Workforce Replacement

Of course, the introduction of fully automated systems or software supported by AI could give rise to the general concern that they would replace workers, similar to the way manual work was replaced during the industrial revolutions. However, this fear is unfounded since the aim of digitization has never been to replace experts with software but to use computers for low-level and time-consuming tasks and to improve the quality and speed of processes.

Enhancing Efficiency and Accuracy

For example, a system that tracks and archives samples and the corresponding metadata can minimize mix-ups or loss of samples. Automation and AI can handle repetitive and routine tasks with precision and consistency, reducing the likelihood of errors. This enables laboratory personnel to focus on their core competencies and perform higher-level tasks that require their expertise.

Optimizing Time and Expertise

In this way, laboratory personnel have more time to focus on core competencies, which ultimately means improved sample handling in the laboratory and higher-quality analysis. Digitization streamlines processes, eliminates manual data entry, and reduces the need for repetitive manual tasks. This empowers lab staff to allocate their time and expertise to more critical aspects of their work, such as result interpretation, data analysis, and decision-making.

How can a digital laboratory operate more efficiently?

Improved Quality and Working Environment

The fact that the change will enable higher quality output is just one of the benefits of many of the digital changes. It also offers the opportunity to create a more pleasant working environment as tedious tasks could be eliminated or automated. By reducing manual and repetitive tasks, digitalization allows laboratory personnel to focus on more engaging and intellectually stimulating work. This can enhance job satisfaction and overall employee well-being.

Enhanced Data Transfer and Resource Efficiency

Data could be transferred much more easily, ensuring seamless communication and collaboration between different laboratory processes and stakeholders. Digitalization also provides opportunities to optimize resource allocation and utilization in various processes. By streamlining workflows and automating resource-intensive tasks, laboratories can achieve significant resource savings, leading to cost reductions and increased efficiency.

Consideration of Long-Term Cost-Saving

Especially the long-term cost-saving is an important aspect of the decision to take this step, considering the high level of investment for the digitalization change. While there may be upfront costs associated with implementing digital changes, the long-term benefits in terms of cost savings and operational efficiency outweigh the initial investment. By streamlining processes, reducing errors, and optimizing resource utilization, laboratories can achieve substantial cost savings over time.