Synopsis

Quality control measures are essential for ensuring the accuracy and reliability of bone marrow testing, and the paperless system provides several advantages over traditional methods. The system includes quality control checks at various stages of the process, from data entry to report generation. Get to know how Dr. Ton Ermens and his team transitioned into a completely paperless process.

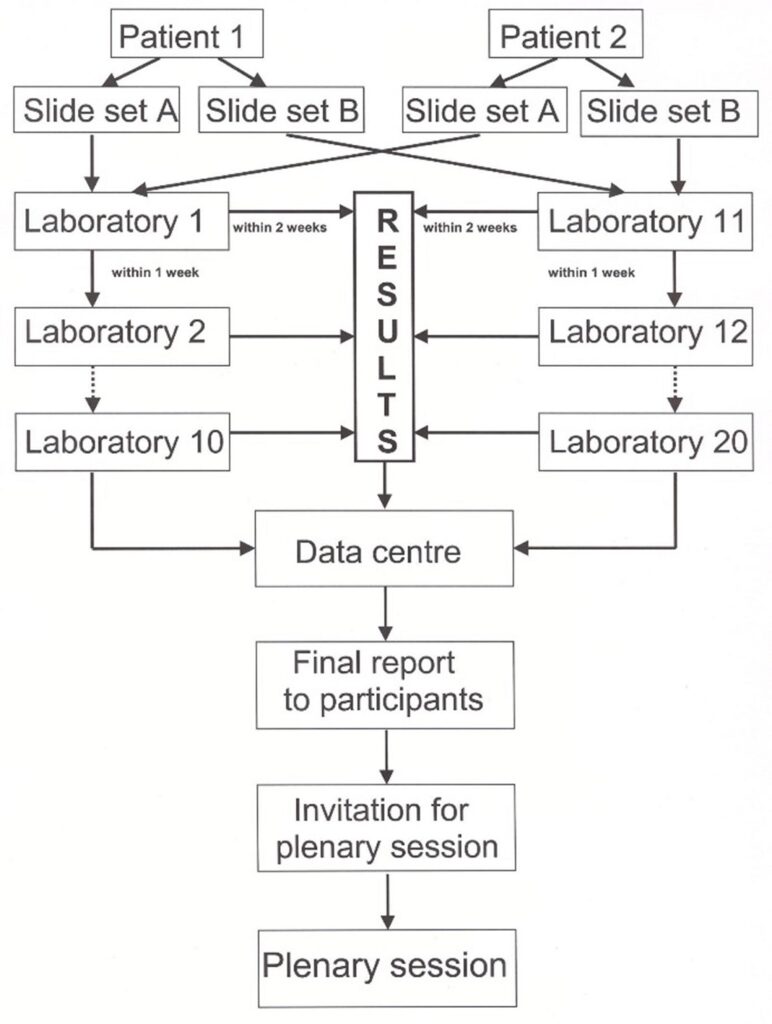

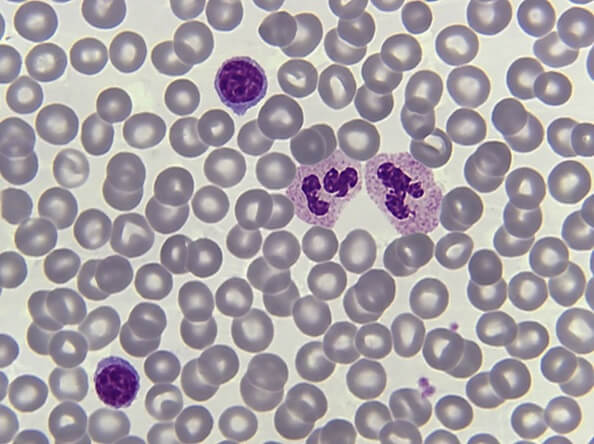

This is how a blood smear looks under the microscope. The grey circles are red blood cells, and the purple ones are white blood cells. In the case of blood and bone marrow smears, the morphology and cytology tell us a lot. There can be variations in color in case of malignancy or infections. That is why we control the quality of the evaluations made by the laboratories that are looking at blood and bone marrow smears to make sure they are doing an accurate job.

Listening to Dr. Ton Ermens talk about his work is fascinating. I have learned so much from him about external quality assurance in cytology and hematology, as I have worked with him closely in the last couple of years. Recently, I had the great pleasure to interview him at one of our latest webinars.

Why is it important to look at blood and bone marrow smears?

Dr. Ermens: What happens is that blood is produced in the bone marrow inside the bones of the sternum and the pelvis. The microscopic evaluation of the smears gives us a lot of information about what’s happening in the bone marrow and the blood. We look at the quantity, the size, and the color of the for example. This analysis is important for the diagnosis of anemia, lymph node cancer, and especially leukemia and pre-leukemia. This information is also very important for the treatment of these diseases. This is why we are monitoring the quality of the evaluations as part of our quality control programs in the Netherlands.

What is the conventional way of doing quality control (QC) and what are some of the weaknesses of performing it that way?

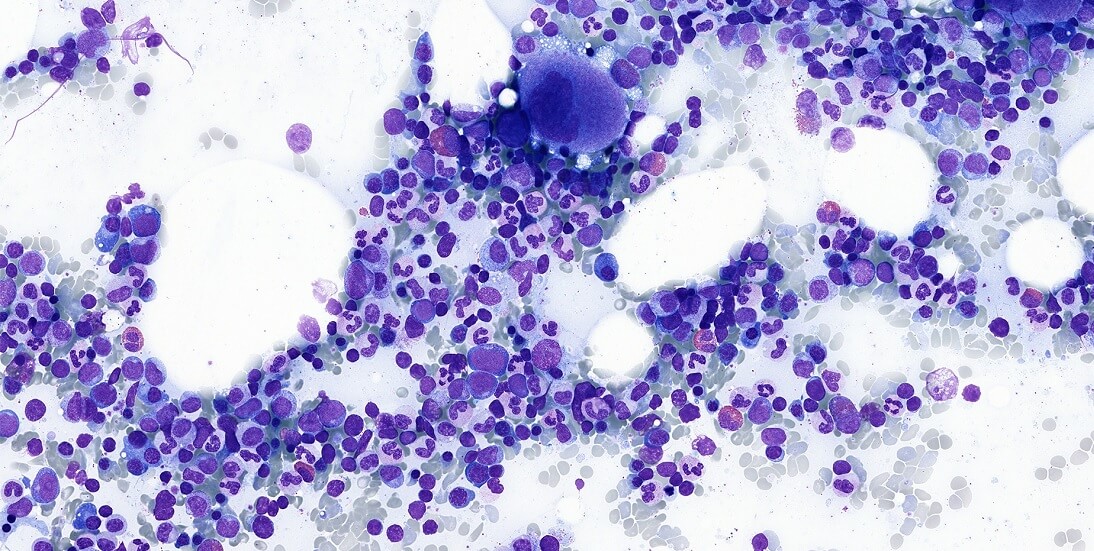

Dr. Ermens: We started doing quality control of bone marrow about twenty years ago. We were the last to start a quality control program because bone marrow smears are so scarce. You see, when we take bone marrow from a patient, we take about 1 ml, that’s not much at all.

We used to send physical test glass slides to laboratories in the Netherlands. The slides would stay at lab 1 for a week, then move to lab 2, and so on. Every lab would have one week to evaluate and make their conclusion. After a journey of 10 labs, the slides would have to be returned to the reference lab. And all the participants would turn in their results to the data center, which would send a final report to all the participants. Every 6 months, we would invite the labs to a plenary session to discuss the cases.

Because it took so long, we could not reach out to all the participants in the Netherlands. There are about 65 labs doing bone marrow analysis in the Netherlands. So we divided the country into 4 regions and every region ran its own bone marrow QC program separately.

To add, transport and delivery of the slides sometimes didn’t work very well. Sometimes they were broken, causing further delay in the process. Sometimes there were discussions on the quality of the sample.

When did you start thinking about a new process and what was the pushback in terms of digital pathology?

Dr. Ermens: About ten years ago, when we started thinking about a digital process, the resolution of the scans wasn’t as good as what we wanted them to be. We looked at a lot of solutions, but they couldn’t give us what we wanted. The resolution, the color, and the contrast were not good enough.

The systems used to present the slides to the participants who were not working for us, or it was too complicated to access the scans after a round. For example, we had to send DVDs to the participants. This was not the way we wanted to work. We wanted to go paperless.

Then we came across PreciPoint and its PreciCloud. It was love at first sight. The images were perfect. The quality was so good that we started working together. I went over to the company, and the team was very willing to work with me on how we can solve our problem.

What were some of the features that you needed to have?

Dr. Ermens: The most important was resolution. Then, we needed a system that was easily accessible. And for our bone marrow participants, we wanted to be able to adjust the contrast, color, and brightness of the scans to the taste and preferences of the participants.

How does the digital solution improve the work of the QC administrators?

Dr. Ermens: There used to be lots of discussions around the images, like what participants could, or could not, see in the samples. Now we can simply open the images and look at them together in our virtual plenary meeting. The images are available after the QC round, so participants can go back to them after the results have been sent. It saves a lot of discussions.

Our logistical nightmares are over. No more lost or broken slides. And we can also add new specimens to the program. We can send new types of images such as pleural effusions or send a combination of images to give the whole picture of the patient.

What are some of the challenges of the new QC program?

Dr. Ermens: The challenge with bone marrow slides is that they are not plane, but more like the Rocky Mountains. The only way to get a good view is to scan at several levels and then put all the information together (z-stacking). This is exactly what happens with the images we get from PreciPoint. Participants see only one layer but this layer has all the information of all the layers of the bone marrow sample.

This is extremely important for our applications, for example, bone marrow iron staining, which is used to detect ringed sideroblasts. To make this kind of evaluation, you need to see the cells in their depth, like a 3-D view.

Another challenge is the file size. Each scan is 1-2 GB. This is half a movie. So, you need to have a solution in terms of storage space.

Last but not least, the participants need to be using screens with a good resolution to review the slides.

Describe the new QC program and how it works now.

Dr. Ermens: Now, our process is completely paperless. We run the program twice a year, with two patient cases. We send an email to all the participants with all the information and the links to the images inside the PreciCloud. The participants have 6 weeks to reply to the QC Institute. 2-3 weeks later we send out the results by email.

What advice do you have for QC groups who want to start working digitally?

Dr. Ermens: Here are my top 3 pieces of advice if you are starting a digital QC program:

- Only scan perfect glass slides so the participants won’t have the possibility to complain about them.

- Don’t use routine slides, but new slides that are clean, and have no oil immersion that gets dirty.

- Instruct the scanning technician on the scanning area and review the scans in advance.

If you want more advice on how to run a QC quality control program digitally, see the full recording of the webinar for free:

By loading the video, you agree to YouTube's privacy policy.

Learn more

Conclusion

To ensure the precision and dependability of bone marrow testing, quality control measures are crucial. Adopting a paperless system offers several benefits over conventional approaches. The system comprises quality control verifications at different stages, ranging from data input to the production of reports. However, in the beginning, there were many limitations when it came to the resolution, the color, and the contrast. The images produced were not of high-quality, thus impacting the output. Experience how Dr. Ton Ermens benefitted from our all-in-one platform for virtual microscopy PreciCloud.

Connect with our PreciCloud Experts

Interested in learning more about PreciCloud or have specific inquiries? We’re here to help. Use the form below to get in touch with our experts.

Your privacy is important to us. PreciPoint uses your information to contact you about relevant content, products and services.

You can unsubscribe from any communication at any time via the footer of our emails. You can find more information in our data privacy policy.